Discover the power of Real-Time Radiography (RTR) — the future of Non-Destructive Testing (NDT). At IPEC Inspection, we deliver advanced RTR solutions that provide instant, high-resolution imaging for fast, accurate, and cost-effective inspections across various industries. Whether you’re in pharmaceuticals, oil & gas, aerospace, automotive, or manufacturing, our RTR services help you reduce downtime, improve safety, and make smarter decisions.

What is Real-Time Radiography (RTR)?

Real-Time Radiography (RTR) is a non-destructive testing method that uses x-rays or gamma rays to inspect materials or components in real time. Unlike traditional radiography, which involves capturing static images on film or digital sensors, RTR allows continuous observation of internal structures, providing instant feedback and the ability to monitor processes as they happen. To do this, we use digital detectors to produce live, high-resolution images, allowing our inspectors analyse the internals of components in real time. RTR delivers rapid, dynamic inspection capabilities that are now becoming invaluable across industries like pharma, oil & gas, automotive, and manufacturing.

How It Works

- Radiation Source: X-ray tubes or gamma ray sources emit penetrating radiation.

- Subject Placement: The object to be inspected is placed between the source and the imaging system.

- Image Capture: A digital detector (such as a flat panel detector, image intensifier, or scintillator) captures the transmitted radiation.

- Image Display: The captured data is processed and displayed on a monitor in real time.

- Analysis Software: Operators can view, record, and enhance images instantly by adjusting parameters which aid the inspection detail.

Advantages of Real-Time Radiography

1. Instant Results

RTR offers immediate imaging and no film processing delays, enabling faster decision-making and quicker turnaround in inspection workflows.

2. Reduced Downtime

Because of its speed and efficiency, RTR minimizes operational interruptions, particularly important in time-sensitive industries like pharmaceuticals, oil and gas or power generation.

3. Digital Image Storage and Processing

RTR supports remote viewing, real-time collaboration, and post-processing enhancements (zoom, contrast adjustments, measurement tools). Digital files are easily archived, shared, and compared over time.

4. Enhanced Safety

Digital systems reduce the need for film processing chemicals and allow remote viewing, minimizing exposure risk for technicians.

5. Cost Savings Over Time

Although initial setup can be expensive, the lack of consumables (like film and chemicals), reduced labour, and faster inspections lead to significant long-term savings.

Common Applications in Industry

- Weld Inspection: Evaluate weld integrity in pipelines, pressure vessels, and structural components in real time.

- Casting Inspection: Identify voids, cracks, and inclusions in cast parts instantly.

- Aerospace Components: Monitor structural integrity of critical aircraft parts.

- Electronics and PCBs: Inspect solder joints and internal structures of electronic assemblies.

- Dynamic Processes: Monitor valve operations, rotating parts, or fluid flows inside systems.

- Automotive Manufacturing: Verification of cast parts (engine blocks, transmission components). Weld integrity checks in vehicle frames and exhaust systems.

Limitations and Considerations

While RTR offers many benefits, certain limitations should be acknowledged:

- Initial Cost: Equipment can be expensive, though ROI is often achieved through efficiency.

- Resolution vs. Speed Trade-off: Some high-speed inspections may sacrifice image clarity. Different digital detectors may need to be purchased for thin walled components or welds for example.

- Radiation Safety: Still requires strict adherence to radiation safety protocols and shielding standards, however exposures are generally drastically reduced.

- Technical Skill Requirement: Operators still require training in both RT methods (Film and Digital) however the principles of RT testing are still more or less the same.

The Future of RTR in NDT

The future of RTR is being shaped by advancements in:

- Artificial Intelligence & Automation: AI-driven defect recognition and image analysis are streamlining inspections.

- Portable Systems: Compact, rugged RTR setups are increasing accessibility for field applications.

- Cloud Integration: Remote data access and analysis allow real-time decision-making across global teams.

- 3D Radiography: Integration with computed tomography (CT) is allowing RTR to evolve into full-volume analysis in near real time.

IPEC Case Studies

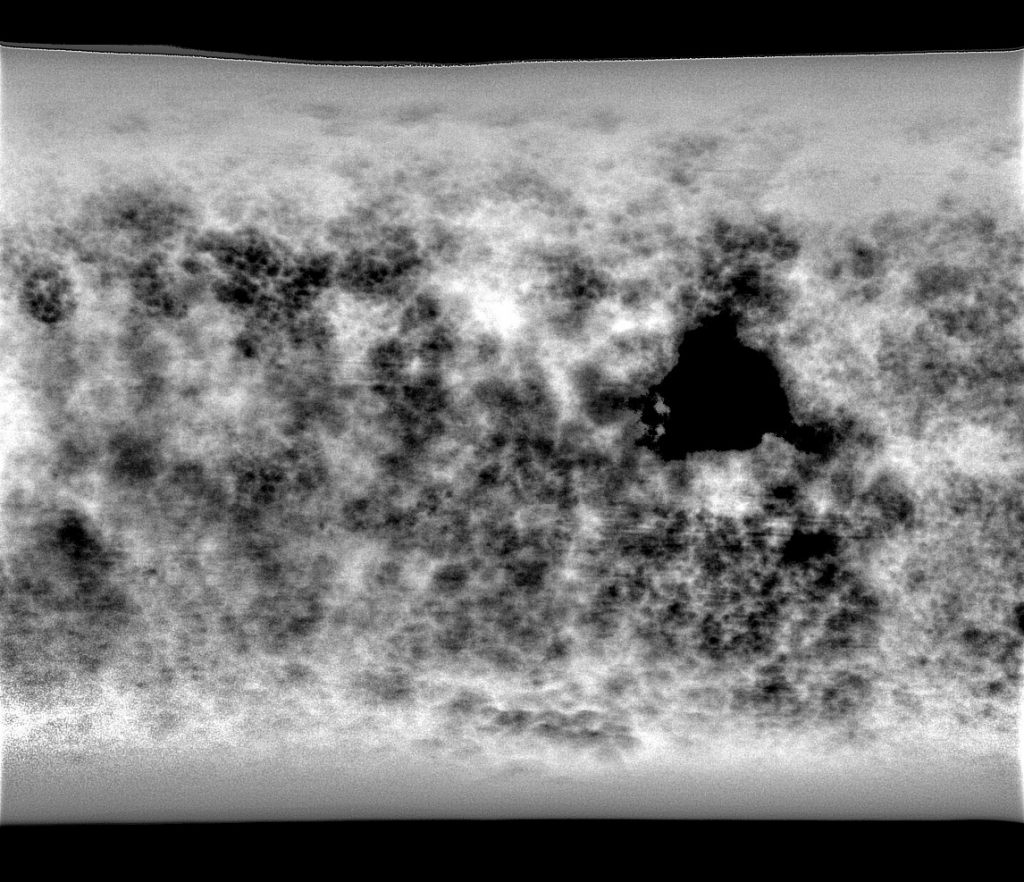

Example 1 – 8″ Carbon Steel, Sch. 40 Pipe with visual evidence of external corrosion. Item was removed from site and provided to IPEC for assessment.

Example 1 – RT Digital Image providing evidence of significant corrosion within the pipe

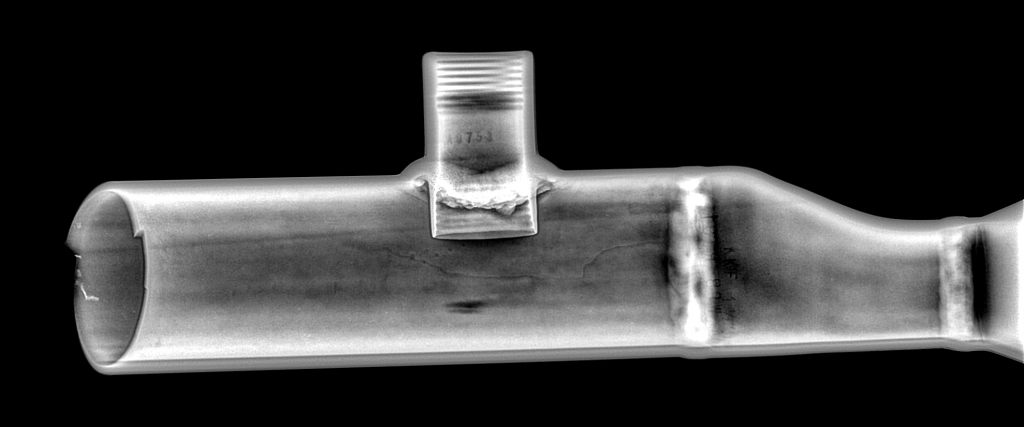

Example 2 – 1.5″ Carbon Steel, Sch. 40 Pipe which failed on site

Example 2 – RT Digital Image providing evidence of defects. Pinholes and cracking was detected using the RTR method and provided to the client.

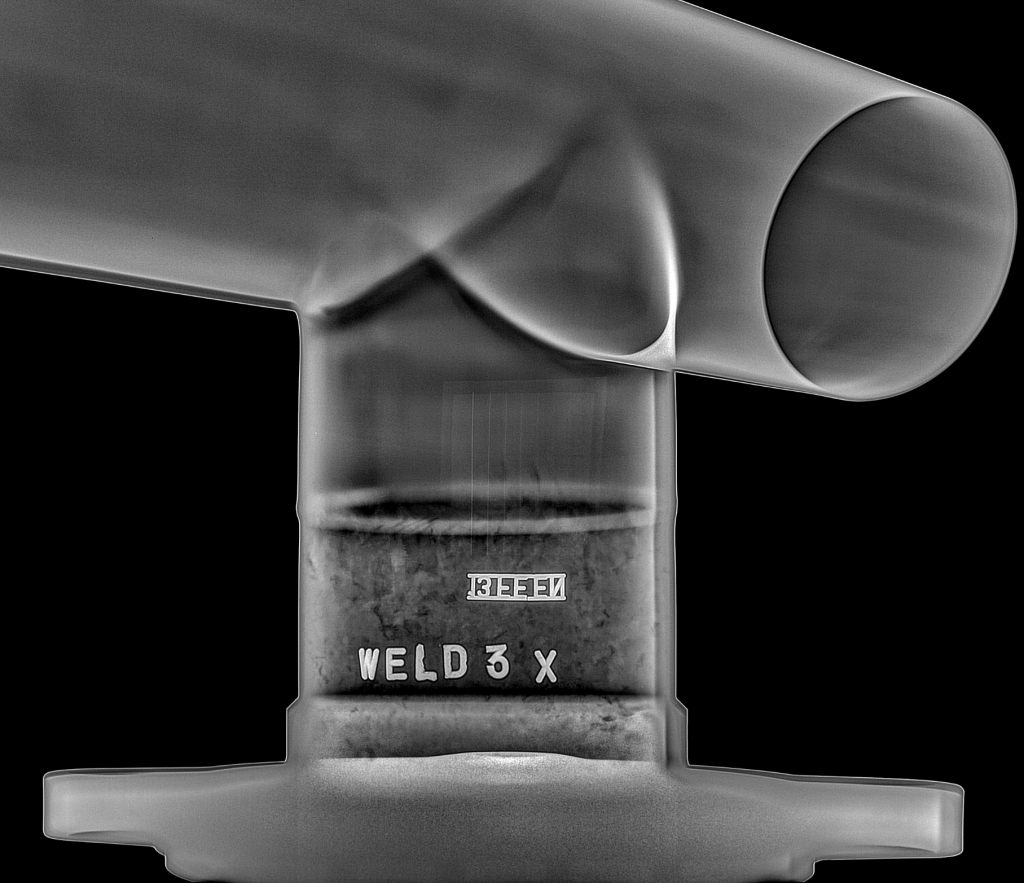

Example 3 – A Stainless Steel (316) Cast Fitting orbitally welded to a Stainless Steel (304) Tee which showed evidence of wrinkling on site.

Example 3 – RT Digital Image providing evidence of wrinkling and internal cavities after welding.

Conclusion

Real-Time Radiography is revolutionising NDT by providing fast, accurate, and cost-effective inspections. Its ability to deliver immediate digital imaging makes it indispensable for industries requiring high precision and efficiency. Real-Time Radiography is more than just an upgrade to traditional radiography—it’s a leap toward smarter, faster, and more comprehensive inspections.

At IPEC Inspection, we are utilising a state-of-the-art RTR system which is ensuring the highest quality inspections for our clients. As industries demand greater efficiency and precision, RTR is becoming an essential tool in the NDT toolkit.

Contact us today to learn how Real-Time Radiography can enhance your inspection process! Contact Us

Related Topics;

Advanced UT (Phased Array & ToFD) in Lieu of Radiography

Author: James Murphy, Operations Manger of IPEC Inspection Ltd.