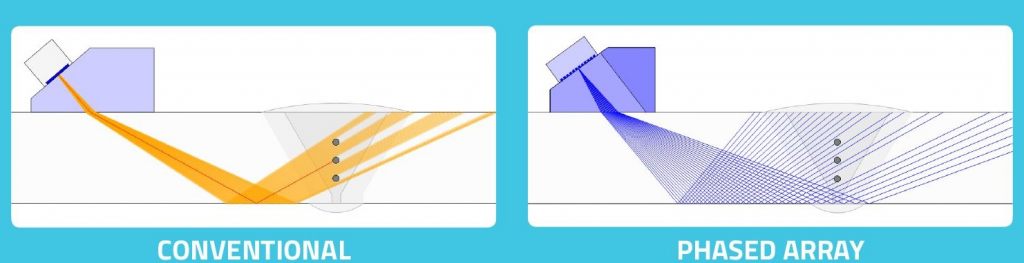

Phased Array Ultrasonic Testing (PAUT) is an advanced non-destructive examination technique that utilises a set of ultrasonic testing (UT) probes made up of numerous small elements, each of which is pulsed individually with computer-calculated timing (“phasing”). When these elements are excited using different time delays, the beams can be steered at different angles, focused at different depths, or multiplexed over the length of a long array, creating the electronic movement of the beam.

The beam from a phased array probe can be focused and electronically swept across an inspection piece without moving the probe itself. This differs from single element probes (also known as monolithic probes). These more conventional probes need to be physically moved or turned to cover larger areas, which is not required for PAUT.

Phased array probes can be used manually in a free running mode scrubbing the surface of a component, attached to an encoder to record position, or mounted on a semi-automated or motorized scanner for optimum productivity. Using phased array probes in direct contact with the component, whether mounted on a hard wedge, a water delay line, or even inside a wheel probe, gives inspectors the ability to quickly scan large areas for corrosion, cracking, and other defects with high resolution. PAUT can be used to inspect almost any material where traditional UT methods have been utilized and is often used for weld inspections and crack detection.

How Does Phased Array Work?

Phased array ultrasonic testing probes are made up of several piezoelectric crystals that transmit/receive independently at different times. By varying the timing, for instance by making the pulse from each transducer progressively delayed going up the line, a pattern of constructive interference is set up that results in radiating a quasi-plane ultrasonic beam at a set angle depending on the progressive time delay. In other words, by changing the progressive time delay the beam can be steered electronically. It can be swept like a search-light through the tissue or object being examined, and the data from multiple beams are put together to make a visual image showing a slice through the object.

(Example of a Phased Array Weld Scan using a Sonatest Veo+ Flaw Detector)

There are a number of different techniques that can be used with PAUT systems such as;

Total Focusing Method (TFM)

This method involves the application of the basic phased array focusing principle at a defined region of interest. The inspection region is segmented into a grid of positions, or pixels, with beamforming applied to each pixel in the grid.

Full Matrix Capture (FMC)

Full Matrix Capture (FMC) enables the collection of all the possible transmit/receive combinations. Combining FMC data with advanced imaging algorithms like Total Focusing Method (TFM) allows for areas to be inspected with ideal wave focus at all points on the image. These advanced techniques allow trained personnel to provide better defect detection, imaging, characterization, and sizing on some of the most demanding applications.

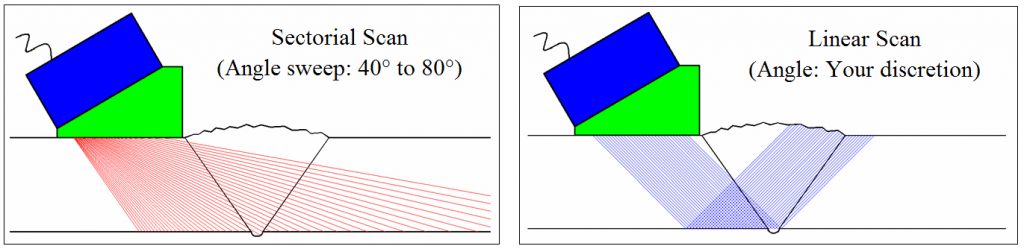

Electronic Scanning

Electronic scanning reproduces the inspection performed by manually moving a standard UT probe. An ultrasonic beam is electronically translated across the entire probe, allowing for faster inspection while limiting mechanical displacement. The technique can be performed with an S or and L wave and can be combined with beam focusing and beam steering.

Sector Scanning

Sector scanning uses electronic delay laws to electronically change ultrasonic beam angles in a defined sector. This means that only one transducer is needed to inspect components under different angles and is also much faster than standard angled beam UT, displaying cross sections of the specimen in real time and allowing for easier interpretation. This technique can be combined with electronic focusing and used for L- and S-waves.

Advantages of PAUT

The advantages of phased arrays over conventional ultrasonic probes include improved portability, convenience, inspection speed, and safety. A phased array is more robust and easier to use than conventional single-element probes, it provides improved efficiency, and it can capture hundreds of signals at once which drastically reduces the number of false alarms. PAUT inspection strategies can be optimised to improve flaw detection when used alongside simulation, while data recording and traceability are also greatly improved.

Phased array ultrasonic testing also provides a permanent record, doesn’t produce radiation and can be used for several applications. Because PAUT can detect defects at the surface and into the volume of a weld (with no dead zone), it also gives information about the lateral position of a defect (depth and height).

- Coverage – By steering, focusing, and scanning the transducer beams, PAUT systems can be used to inspect large surface areas quickly with high resolution.

- Speed – Rapid coverage of larger surface areas means PAUT can typically be conducted more quickly than conventional UT.

- Accuracy – By emitting beams of multiple different angles sequentially, PAUT is able to create detailed and accurate cross-sections of an asset, thereby increasing the probability of detecting anomalies.

- Repeatability – PAUT can easily be used for repeat scans due to its high degree of accuracy and consistency.

- Flexibility – PAUT has proven to be an effective technique for inspecting more complex geometries such as elbows, bends, and nozzles. PAUT is also particularly useful in situations where there is limited access for mechanical scanning because it’s able to sweep the beam without moving the probe.

- Safety – Using a semi-automated or motorized PAUT scanner avoids exposing inspection personnel to potentially dangerous environments. Moreover, PAUT is an effective alternative to radiographic testing, eliminating the safety hazards associated with radiography.

Disadvantages of PAUT

While PAUT delivers a number of advantages, there are a few disadvantages that need to be considered too. These include;

- Cost – Compared to conventional ultrasonics, PAUT may require a greater initial investment in equipment and experienced technicians, however these costs are frequently offset by the increased flexibility and a reduction in the time required to perform a given inspection.

- Training – PAUT often requires additional operator training to ensure the effectiveness and accuracy of the inspection results.

Where can Phased Array be Used?

Ultrasonic phased array systems can potentially be employed in almost any environment where conventional ultrasonic flaw detectors have traditionally been used. Weld inspection and crack detection are the most important applications, and these tests are done across a wide range of industries including aerospace, power generation, petrochemical, metal billet and tubular goods suppliers, pipeline construction and maintenance, structural metals, and general manufacturing. Phased arrays can also be effectively used to profile remaining wall thickness in corrosion survey applications.

Conclusion

Phased array ultrasonic testing provides a number of advantages and can be used in a range of applications and industries. As a non-destructive testing method, it is more reliable, effective and faster than many other methods, such as radiographic inspection.

While there are some drawbacks, with the correct training and when used on suitable applications, users can perform inspections of material thickness, welds, corrosion, adhesives and more.

Source/Credit: Wikipedia/Phased_Array_Inspection, twi_technical_knowledge, inspectioneering_phased_array & olympus_phased_array_tutorials

Author: James Murphy, Operations Manger of IPEC Inspection Ltd.